Application of microwave high-temperature sintering roller kiln on household porcelain

一.Microwave sintering equipment now widely used in all kinds of high quality ceramics (like high-grade daily-use porcelain) ,fine ceramic, electronic ceramic device: PZT piezoelectric ceramic,piezoresistor , etc

Microwave sintering or microwave combustion synthesis means that using microwave radiation to replace traditional heat . Mixing material evenly or pressing molding material to absorpt microwave energy by itself in advance to reach a certain temperature, which lead to the process of combustion synthesis reaction or complete sintering. Due to it is completely different from traditional heating mode ,microwave sintering has its own distinguishing features

1.Principle of microwave dielectric heating

Once chemical raw materials were put into the microwave elecrtical field, its polar molecules and non-polar molecules will cause polarization then become even molecular. The orientation should according to electric field, as the electric field belongs to alternating electric field, the dipole will rotate and vibrate according to the change of electric field.For example, the frequency is 2450 MHZ, rotate and vibrate with 2.45 billion times per second,which could cause mutual friction reaction that is similar to between molecules,then absorbing the electric energy to heat,the object itself become a heating element.

2. The difference between microwave heating and traditional heating

When heating in traditional way , ignition always start from the sample’s surface, burning from surface to sample’s internal part and finally complete reaction sintering. By microwave radiation, the situation will be different .Because of microwave’s strong penetrating power, it can through deep into the sample internal part, which can first make sample center’s temperature lifts quickly and then reach the ignition point and cause combustion synthesis. Sintering wave spread along the way from inside to outside, which can make the whole sample heating uniformly , finally complete sintering reaction .Temperature gradient (dT/dT)produced by microwave ignition in samples is smaller than that in traditional ignition way.That’s to say, the spread of sintering wave in microwave sintering process is much more uniform than that in traditional heating mode.

The experiment shows that, when the sample’s pressure density is high, the spread rate of combustion wave caused by traditional heating is greatly reduced, even quenching by itself and cannot self-ignition (commonly known as didn't burn through).However, if you use the microwave irradiation, due to the rise of temperature is the result of absorpting or diffusing microwave energy of reactive material itself .As long as the microwave generator constantly give energy to the sample,the temperature will soon reach ignition temperature (T1) . Once reaction caused,the released heat will further raise temperature to ignition temperature (T2), the ability of absorpting microwave radiation will increase simultaneously.It can ensure that the reaction can be kept at a high enough temperature (T3 > T1), until the reaction completed.

3.The process of microwave combustion synthesis or microwave sintering can be controlled.

We can control the spread of combustion wave artificially through adjusting a series of parameters according to the requirements of the product properties. It is significant feature of microwave combustion synthesis compared with traditional technology.We can regulate microwave power through adopting adjustable microwave generator to control sample’s absorption or dissipation to microwave energy directly ,which can meets our requirements more directly.

二、Application of microwave high temperature sintering roller kiln on high-grade household porcelain.

The conclusion is based on our company and some company in chaozhou Guangdong 's experiment and application of using microwave high temperature sintering kiln (biscuit firing and glaze burn),when exporting advanced daily-used china to European and American markets. The advantages are as follows:

1. The quality is greatly improved, mainly in strengthening density , brighting product color and no deformation.

2. The firing time greatly shorten, the productivity is greatly improved.

3. Low rejection rate, the acceptance rate is about 98%

4. Use computer control and automatic production, which can reduce the cost of labor.

5. Compared to conventional furnaces,it can save energy over 40%.

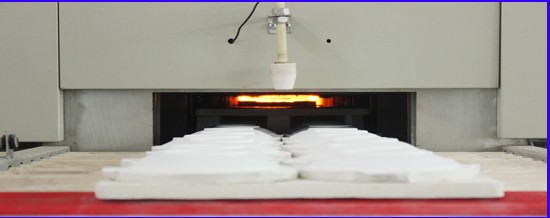

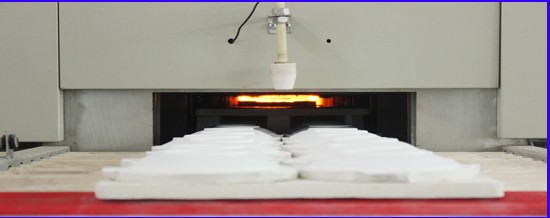

三、Picturs of microwave high temperature sintering roller kiln and firing products.

3.1 RWEG microwave high temperature roller kiln.

3.2 RWEG microwave high temperature roller kiln control system.

3.3 RWEG microwave high temperature roller kiln outlet port.