The manufacturing technique and technological advantageof lithium iron phosphate produced by microwave

1.The preparation method of lithium iron phosphate (cathode material of lithium-ion battery)

Its features is that mixing ferrous oxalic acid, lithium phosphate, sucrose according to their weight ratio 100∶24∶12.5, add high energy ball mill which filling in inert gases in grinding tank, using drying activation treatment 5 - 50hours;take out powder from grinding tank, put it into the furnace which protected by inert gas to carbonize.,then heating to 300℃ with 5-10 / min,isulating 5-10 hours,cooling to room temperature;pressed the powder after carbonizing and then put it into container,put the container into boxing warmer,then put boxing warmer into ndustrial microwave furnace to react, adjust program temperature setting, insulate and react 10 to 30 min under 500℃,while cooling to room temperature, grinding the reaction product by airflow crusher to 400 mesh screen, lithium iron phosphate (cathode material of lithium-ion battery) can be produced.

2 The manufacturing technique of lithium iron phosphate (cathode material of lithium-ion battery)

The performance of lithium ion battery mainly depends on the cathode and anode materials, lithium iron phosphate as lithium battery materials appeared in recent years, in July 2005 our contry has developed large capacity lithium iron phosphate batteries. Its safety performance and cycle life is unparalleled, which is also regarded as the most important technology index of power battery .1 c can charge and discharge cycle lifespan nearly 2000 times. Single battery overcharging 30 v cannot burn, puncture can not explose. In order to meet the needs of the frequent charging and discharging of electric vehicle , lithium ion battery produced by lithium iron phosphate positive electrode material could be cascaded. Lithium iron phosphate is non-toxic, pollution-free, safe, wide material source, cheap, long lifespan, etc., which regarded as a new ideal anode materials of lithium ion battery .

This project belongs to the functional energy materials development of hi-tech project, is the key supporting areas of hi-tech industrial development planning of “863” plan ,”973” plan, 11th Five-Year plan ,12th Five-Year plan .

3. Technical characteristics and advantages:

①Adopt simple production process which is easy to industrialization, make use of

automatic control, continuous production, warming fast and easy control, energy- conservation and environment- protection, which greatly reduce the cost of industrialization

②Adopt special mechanical chemical activation, and one-step synthesis , multidoped ,spot compound creative technology,which can shorten the reaction time, reduce the reaction temperature, and enhance the stability of the product .

③Adopt unique spot generate nano structure carbon process to produce lithium iron phosphate nano structure carbon composite material,which greatly improve the charging and discharging capacity of lithium iron phosphate, and completely solve the problem that the charging and discharging current of lithium iron phosphate, and the decline of electrode polarization capacity.Due to make use of the characteristics of microwave high-temperature heating technology, sintering material can heating overall which ensured the tap density and product quality,and greatly improved the product performance, can reached the international advanced level of the same products.It has the characteristics of safe,energy saving,high efficiency, environmental protection, which belongs to clean production techniques that the state advocates.

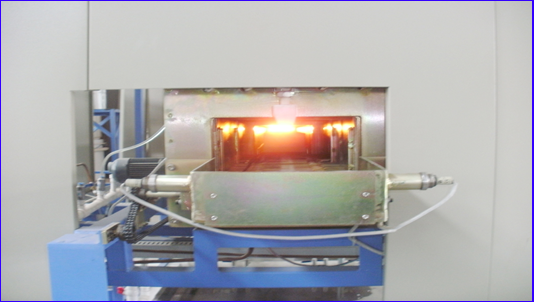

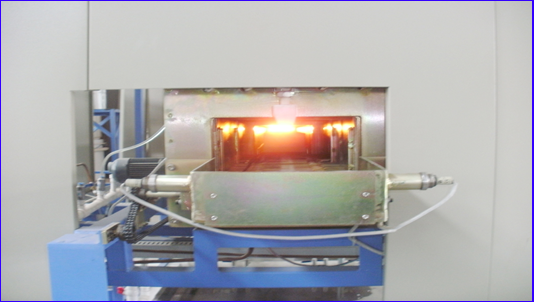

4. Picture of micowave industrial equipment.